Pressure ratio : Up to 3

Efficiency: up to 88%

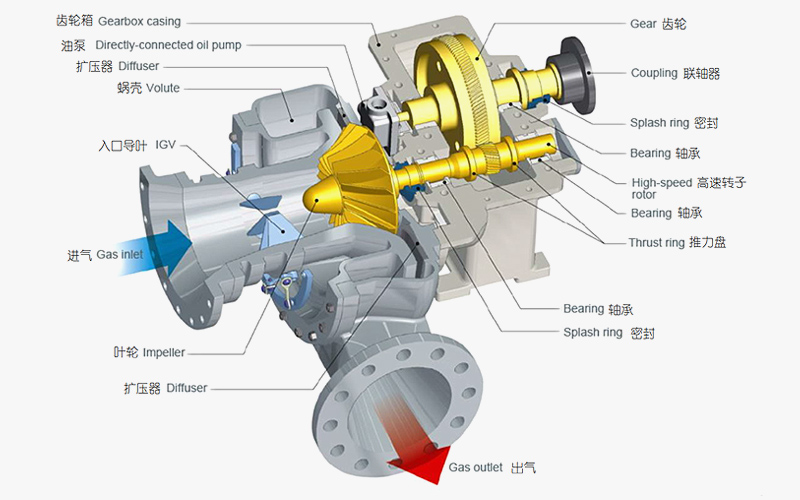

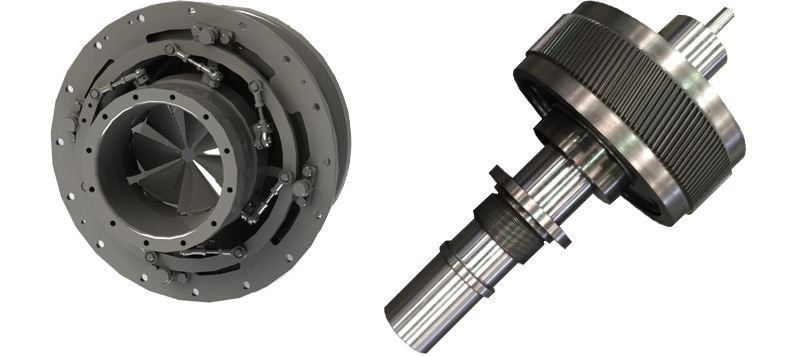

· Rotor: it adopts 3-yuan semi-open impeller and is made by integral milling of CNC five-axis machining center to ensure the accuracy and strength of the impeller.

· Inlet guide vane regulator: the airfoil inlet guide vane is used to adjust the inlet air flow pre-rotation Angle of the blower to achieve the performance adjustment of the blower, and the flow adjustment range is 40-110%.

· Gear: The gear is single-sided helical tooth, the precision of the gear reaches the national standard level 5 (5-GB/T 10096), the surface of the gear is specially hardened, and the service life is more than 100,000 hours.

· Gear box: Tilting tile bearing is adopted for high speed shaft of gear box, with high stability; Gear machining up to ISO level 4, design service life is more than 30 years.

· Oil system design: Advanced finite element analysis software was used to analyze the overall stiffness of the oil station to ensure the reliability of support. The oil system is equipped with an oil mist fan. The oil system runs under negative pressure to effectively solve the problem of oil smoke and lubricating oil spatter in the gear box.

The unit adopts direct oil pump for self-forced lubrication, which can be fully supplied by direct oil pump before the blower stops. There is no need to set the high oil tank for on-site power failure emergency oil supply and its supporting oil pipelines. All the oil pipelines are assembled in the plant, and the on-site installation workload is greatly reduced. The auxiliary oil pump only runs temporarily when the unit is started and stops when the unit is in normal operation.

Unit monitoring parameters:

1. Vibration and axial displacement of high and low speed rotor

2. Bearing bush temperature

3. Inlet and outlet pressure, flow rate and temperature of blower.

4. Oil system pressure, temperature, liquid level height, filter pressure difference

Unit control system functions:

1. Automatic control of oil system, including auxiliary oil pump start and stop, oil pressure control alarm stop, oil temperature control.

2. Automatic control of inlet guide vane opening.

3. Vibration and temperature alarm stop of the unit.

4. Anti-surge system of unit.

5. Wheel opening and coordinated control of multiple units

6. Remote online monitoring of unit status and fault diagnosis.

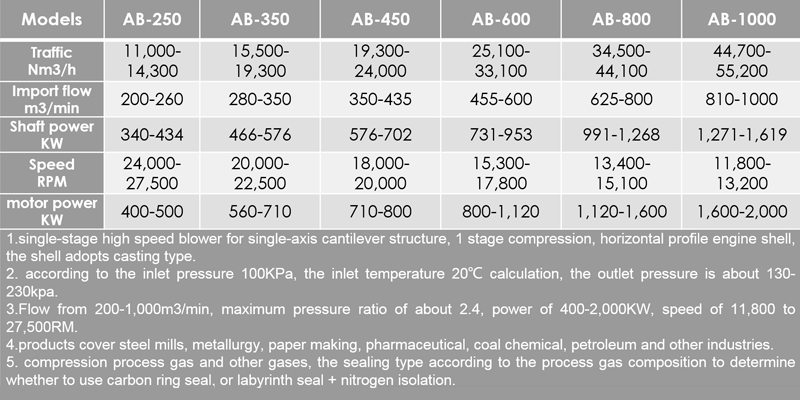

Typical product specifications and parameters:

Pay attention to our

Pay attention to our