AnFan long-term metallurgical industry to provide including: ASJ circulation fan series main exhauster, dry quenching system, regenerative blower, dust pellets by centrifugal fan, high pressure centrifugal blower, static blade adjustable axial flow fan and a series of high quality products, anshan steel peak for metallurgical enterprises relocation and upgrade the overall planning and system layout, installation and debugging services integration solutions.

INDUSTRY APPLICATION

Metallurgical Industry

Metallurgical IndustryProduct application solutions

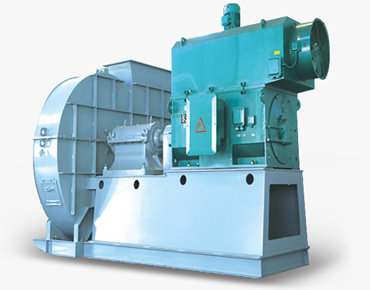

ASJ Series main exhaust fan

Advantage:

・High efficiency

・Wide performance range

・High hardness blade

・The HRC of blade wear liner is more than 62

Service area:

・Main draught fan matching the sintering machine

・100~500 million tons of pellets are installed each year

・Auxiliary main fan

Centrifugal fan for dedusting system

Advantage:

・Wide performance range

・3D blade gives high efficiency

Service area:

・Dust removal system of steel plant.

Pellet hot gas recycling fan

Advantage:

・Special material and design of fan for high temperature

・Reliable wear liner

・Turning gear for booting

Service area:

Hot gas recycling fan for pellet project with the capacity from 1-5 million tons per year.

Centrifugal fan for dedusting system

Advantage:

・ Reliable wear liner

・ Reliableperformanceunder frequently changing rotate speed operatingcondition

・ With nitrogen sealing

Service area:

Circulating fan for dry quenching project with the capacity from 70-160 t/h

High pressure centrifugal blower

Advantage:

・ Wide performance range

・ Milling impeller gives high efficiency

・ Compact structure gives smaller size.

Service area:

High pressure blower for blast furnace, coking, iron making, steel making and sulfur recovery.

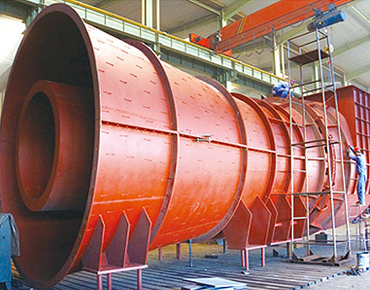

Static blade adjustable axial fan

Advantage:

・ Wide performance range

・ High efficiency

・ Long life time of the blade

・ We use the forged aluminum alloy or low alloy steel as the blade material and spray fusing Ni-WC on the blade based on the different application of fans.

Service area:

Booster fan for FGD and De-Nox project.

Advantage:

・High efficiency

・Wide performance range

・High hardness blade

・The HRC of blade wear liner is more than 62

Service area:

・Main draught fan matching the sintering machine

・100~500 million tons of pellets are installed each year

・Auxiliary main fan

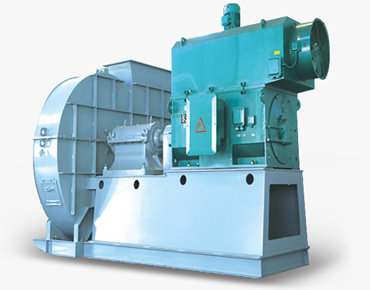

ASJ Series main exhaust fan

Advantage:

・Wide performance range

・3D blade gives high efficiency

Service area:

・Dust removal system of steel plant.

Centrifugal fan for dedusting system

Advantage:

・Special material and design of fan for high temperature

・Reliable wear liner

・Turning gear for booting

Service area:

Hot gas recycling fan for pellet project with the capacity from 1-5 million tons per year.

Pellet hot gas recycling fan

Advantage:

・ Reliable wear liner

・ Reliableperformanceunder frequently changing rotate speed operatingcondition

・ With nitrogen sealing

Service area:

Circulating fan for dry quenching project with the capacity from 70-160 t/h

Centrifugal fan for dedusting system

Advantage:

・ Wide performance range

・ Milling impeller gives high efficiency

・ Compact structure gives smaller size.

Service area:

High pressure blower for blast furnace, coking, iron making, steel making and sulfur recovery.

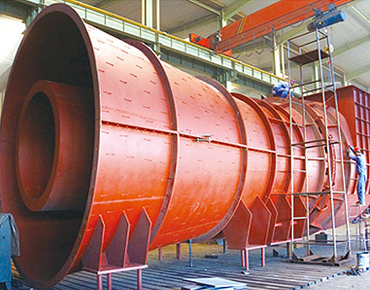

High pressure centrifugal blower

Advantage:

・ Wide performance range

・ High efficiency

・ Long life time of the blade

・ We use the forged aluminum alloy or low alloy steel as the blade material and spray fusing Ni-WC on the blade based on the different application of fans.

Service area:

Booster fan for FGD and De-Nox project.

Static blade adjustable axial fan

Pay attention to our

Pay attention to ourAnshan Gangfeng Fan co., ltd

(0412) 8481010 / 8481011

asfjec@163.com

http://en.anshanfan.com

No.9 Daqi Street Qianshan District Anshan City

About AnFan

Product center

Industry application

COPYRIGHT (©) 2022 anshanfan.com - 辽ICP备20008087号-1 design by maymo.cn